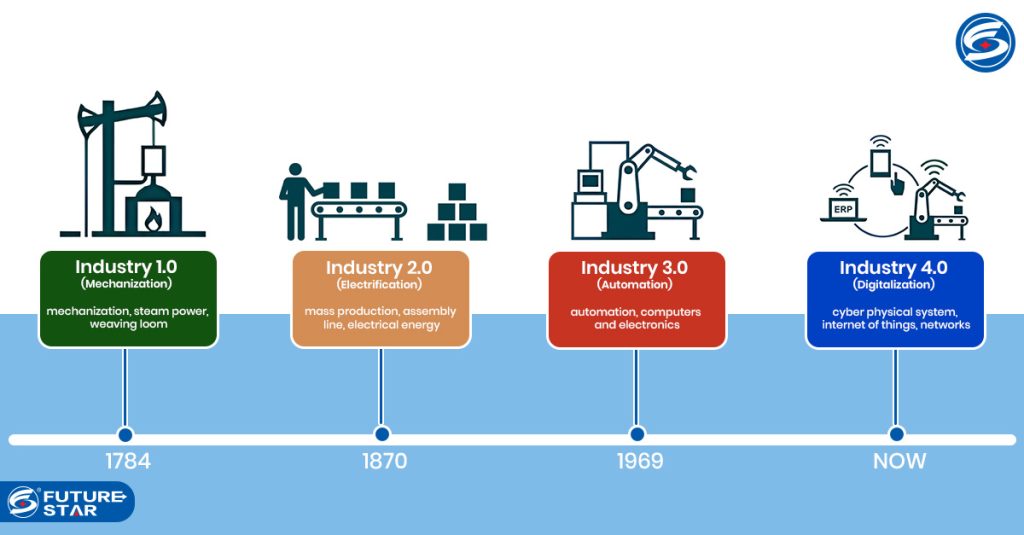

The Important Role of Construction Industry Development in the Digital Transformation Era which continues to be the target of success for Contractors. The emergence of the Digitalization Era in the last 10 decades has resulted in drastic changes in human behavior, especially the use of technology. The impact of the development of digitalization technology today can be felt in various industries.

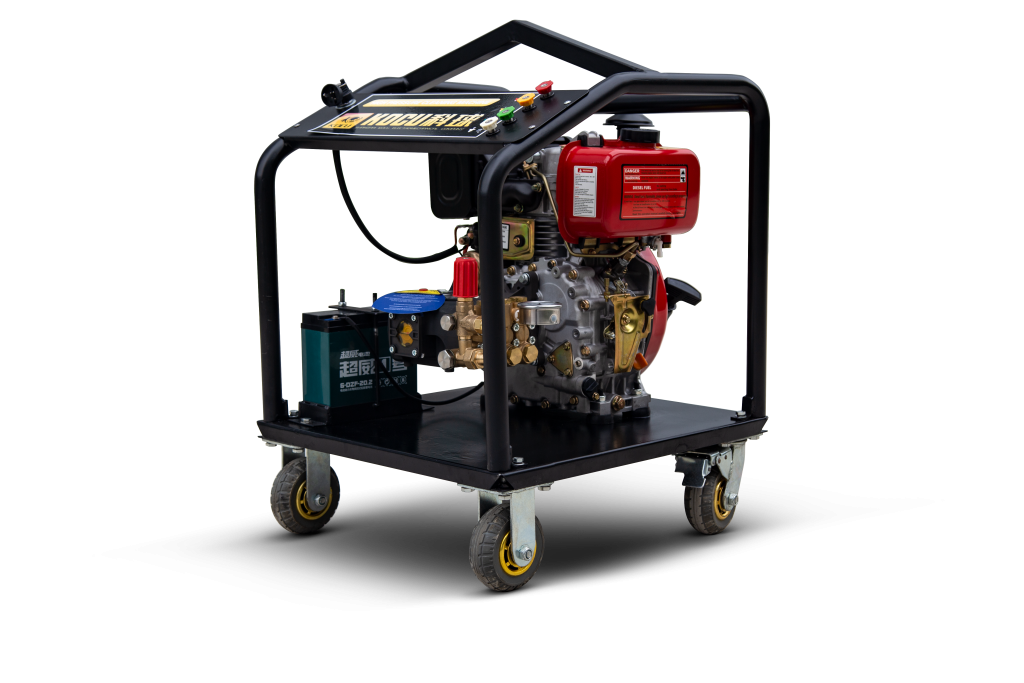

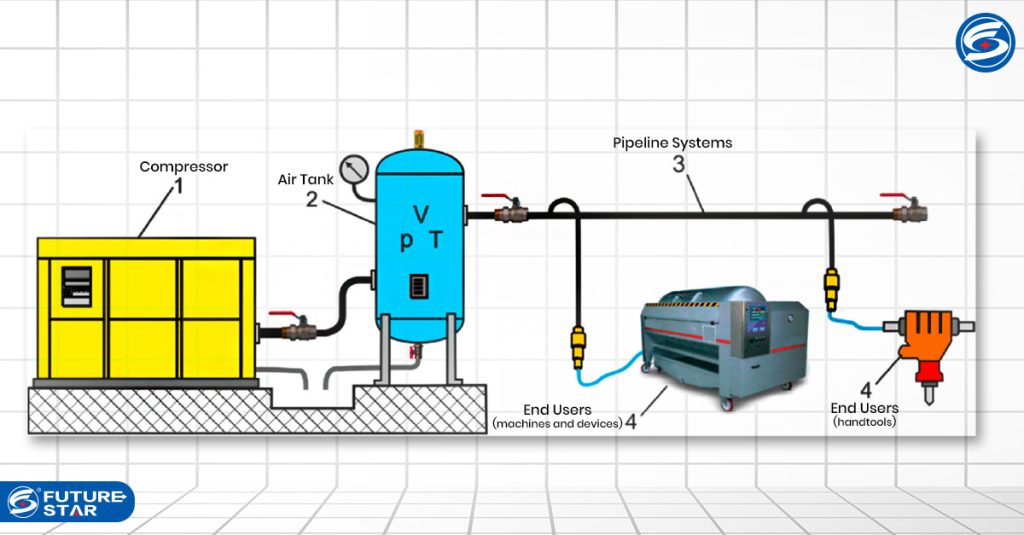

The Construction Industry is one industry where almost all work will require machinery for operations. Such as preparation for the provision of materials, labor, and increased safety in the workplace. This step aims to simplify change management in maintaining accuracy on each project.

Construction Machinery Technology can improve Safety and Mitigate Risks at Work

There are several ways digital technology can improve safety and risk mitigation on construction sites. For starters, these technologies help identify project risks, manage those risks, and create robust mitigation plans. For example, employee tracking can help identify and alert employees to potential hazards on the job.

This allows contractors to see who is on the jobsite and where they are, receive real-time alerts for potential injuries or hazards on the jobsite, and quickly communicate in the event of an emergency.

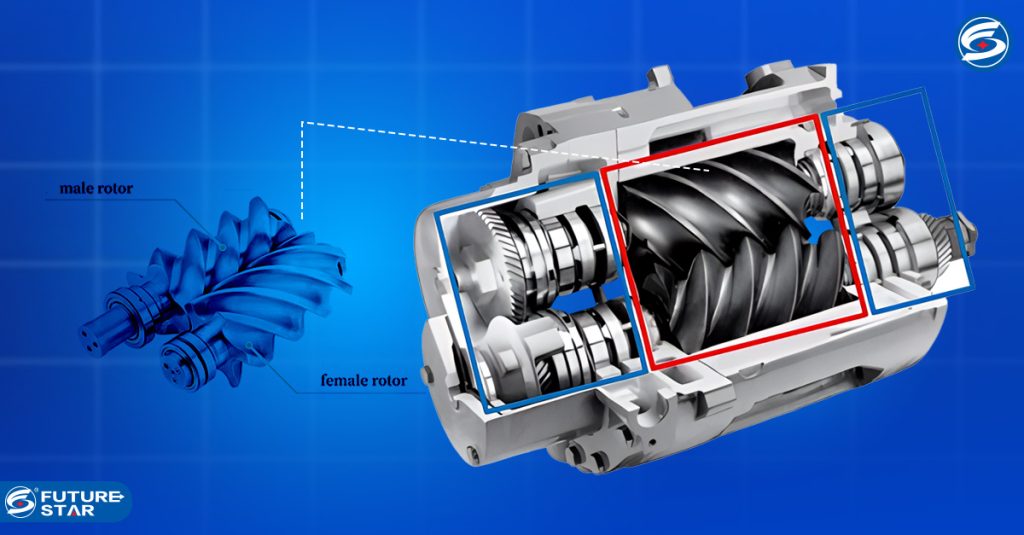

Technological improvement innovations in the field of building infrastructure have ushered in the perspective and creativity of a construction service provider. The creation of these machines is designed to face the globalization of competitors around the world.

Technological developments in machinery are now widely applied at various stages of construction, revolutionizing traditional practices. Our extensive market research revealed the emergence of five types of new technology startups that are utilizing these technologies to reshape the industry.